Distillative separation processes are tested in the chemical industry in laboratory and pilot plants prior to the construction of production plants. By using all-glass distillation columns it is possible to study vapour and liquid streams and other different processes resulting from the characteristics of the product to be distilled. Due to the unlimited observation of these processes PILODIST® distillation columns and systems are used and well known in almost all chemical process engineering institutes of universities around the world for teaching purposes.

The most important aspect for a distillation system is the type of column to be used. Depending on the characteristics of the product to be distilled as well as the mode of operation, PILODIST® is offering different types of columns.

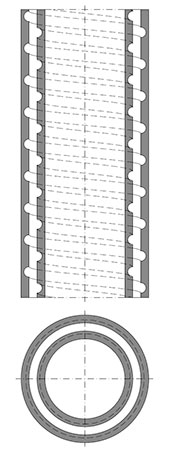

Concentric Tube Columns

|

This column type can be used to solve every distillation problem under atmospheric or reduced pressure condition. At the same time it is most dedicated for the discontinous distillation of very small quantities of thermally sensitive components with molecular weights from 200 up to 2000, like fatty alcohols higher fatty acids, olfactory products, resins as well as animal and vegetable fats and oils. These products can be separated by distillation without being decomposed by operation under reduced pressures. The high separation efficiency of the concentric tube column is related to the physical principle of the mass transfer between the vertically rising vapour and the spirally trickling film of liquid in a concentric annular gap made of glass. The column consists of two concentrically melted, calibrated glass tubes and is an all-glass-construction. Characteristics

|

Dates of available concentric tube columns

| Typ/Type | MRS 255 | HRS 300 C | HRS 500 C |

|---|---|---|---|

| Operating range of flask (ml) | 1-10 | 5-200 | 10-200 |

| active column length (mm) | 200 | 300 | 500 |

| theor. number of plates | 40 | 60 | 90 |

| load at 1000 mbar in cm3/h | 50-400 | 50-500 | 80-1000 |

| load at 10 mbar | 3-23 | 6-50 | 9-115 |

| load at 1 mbar | 1-9 | 2-20 | 5-50 |

| lowest flask pressure (mbar) | 0,1 | 0,01 | 0,02 |

| working contents (ml) | 0,3 | 0,5 | 1,0 |

Bubble Cap Tray Columns

are preferably used for thermal decomposition of gaseous and liquid materials in continuously operating test and pilot plants for rectification absorption and desorption systems. Another important application is the study and demonstration of basic processes in chemical engineering for universities and research labs.

The columns have an almost constant efficiency over a wide load range due to special bubble cap construction. Concentration and temperature gradients can be measured along the column through sample take-off and temperature nozzles.

Bubble cap tray columns are available either with 1 feed and temperature nozzle at the upper column end or with nozzles at every plate, with heating or cooling jacket or with silvered vacuum mantle. The number of plates per column is depending on the built-in-length and the diameter as well. Standard sizes are DN 50, 80, 100.

Characteristics

- all-glass construction for operation from vacuum (100 mbar) up to

- over-pressure of approx 3 bar

- allows load fluctuations

- highly efficient over a wide load range

- recordable concentration- and temperature profile

- optional drain system

Wire Gauze Trickling Columns

are for use with wire gauze packing DNE for rectification purposes under atmospheric condition as well as reduced pressure down to 1 mbar. The packing is made of stainless stell (1.4571) and represents a very large surface due to the geometrical structure. As a result of the large surface which is completely moistened a large distribution effect and a very high separation efficiency can be obtained.

This column type is applied for rectification of solvents, thermally instable substances as well as degassing reactions and absorptions.

Characteristics

- very high separation efficiency over a wide load range

- insignificant loss of pressure

- negligible maldistribution

- packing height 100 – 300 mm

- diameter of the packing 15 – 300 mm

- reproducible results

The following systems, which represent some of the most applied distillation solutions, are standard in a lot of research and development centers. These systems can be modified according to special application or requirements. Please feel free to contact us for any special solution.