News

New distillation tower should make practical lessons more interesting

At the PITO in Stabroek, students today put a new distillation tower into operation. The seventh-year Chemical Process Engineering students thus have the opportunity to put everything they learn into practice.

PETRODIST 100 CC

fully automatic, ASTM D-2892

Processor controlled crude oil distillation system for fully automatic operation exactly conforming to ASTM D-2892 (TBP), latest revision.

The system is computer controlled and designed for fully automatic operation throughout the different distillation runs at different pressure levels which includes: Read the rest

Growth champion 2021 of the German Industry

Encouraging and amazing news in difficult times for all of us:

For the fifth time since 2015 PILODIST has been appointed as one of “Germany’s Growth Champions 2021” by FOCUS Business Magazine in cooperation with the independent institute “Statista”. The Read the rest

Inauguration of PILODIST´s new production hall expansion project

PILODIST proudly announces the inauguration of an additional adjacent new production hall for the assembly and testing of turn-key systems for distillation, extraction and thin-film evaporation.

Following our tremendeous growth over years it became neccessary to grow this area as Read the rest

Receipt of German Patent for Automatic Phase separation

We are happy and proud to announce that the following patent now has been officially been assigned by “Deutsches Patentamt” which is the German patent authorities.

Automatic phase separation

This is a special feature being used in the water removal Read the rest

Thanks to Norbert for 50 years of loyalty

Today was the last work day of Norbert. He joined my earlier family business FISCHER Labor- und Verfahrenstechnik GmbH, founded by my father in 1967 and continued in PILODIST GmbH later on. So he was working for a total of Read the rest

Germany’s growth champion 2017

We are proud to announce that PILODIST GmbH been appointed for the second time as one of the “Growth Champions” of the German industry for 2017 by the German magazine FOCUS in cooperation with STATISTA.

We belong again to the Read the rest

Maxwell-Bonnell-Calculator with new feature

Please use our Maxwell-Bonnell-Calculator to convert actual temperatures (ACT) into athmospheric equivalent temperatures (AET) and to determine the pressure needed in the system so that AET corresponds to the ACT.

The Maxwell-Bonnell Calculator determines the atmospheric equivalent temperature (AET) from Read the rest

PILODIST 250 – Distillation system for continuous and discontinuous (batch) operation

We are proud to display a customized distillation system just recently manufactured and installed by PILODIST engineering team.  The system has been designed to operate under atmospheric as well as vacuum conditions down to 1 Torr in continuous and discontinuous Read the rest

The system has been designed to operate under atmospheric as well as vacuum conditions down to 1 Torr in continuous and discontinuous Read the rest

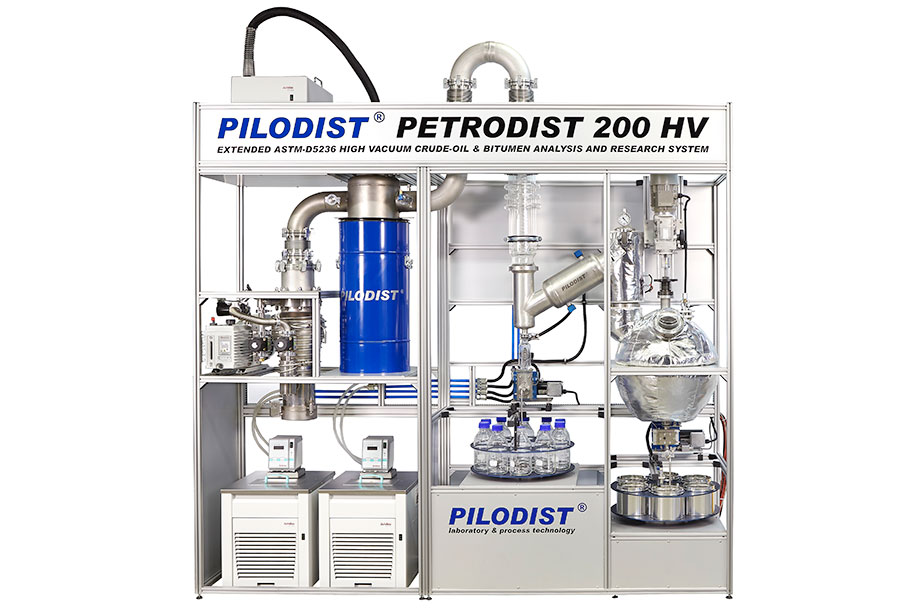

PETRODIST 200 HV – crude oil distillation system for automatic operation following ASTM D-5236

Processor controlled crude oil distillation system for automatic operation following ASTM D-5236 for distillation up to a final temperature of 600° C AET.

The crude oil is charged into a 33 L stainless steel flask for charge of 10-22 L Read the rest

PILODIST GmbH – one of the german companies with utmost growth

We are proud to announce that PILODIST GmbH has been appointed by FOCUS in co-operation with STATISTA as one of the german companies with utmost growth.

We belong to the TOP 500 German growth champions and are listed in the Read the rest