Processor controlled crude oil distillation system for fully automatic operation exactly conforming to ASTM D-2892 (TBP), latest revision.

The system is computer controlled and designed for fully automatic operation throughout the different distillation runs at different pressure levels which includes:

- debutanization

- run at atmospheric pressure

- run at vacuum 100 Torr

- run at vacuum 10 Torr

- run at vacuum 2 Torr

These different distillation runs are performed automatically without any intervention of the operator. The system automatically manages the changes of all involved operation pressure changes from atmospheric to the different vacuum conditions automatically with. The duration of the intermediate cooling procedure in between the different runs is minimized by an intensive cooling of the flask charge as well as introduction of N2 into the system.

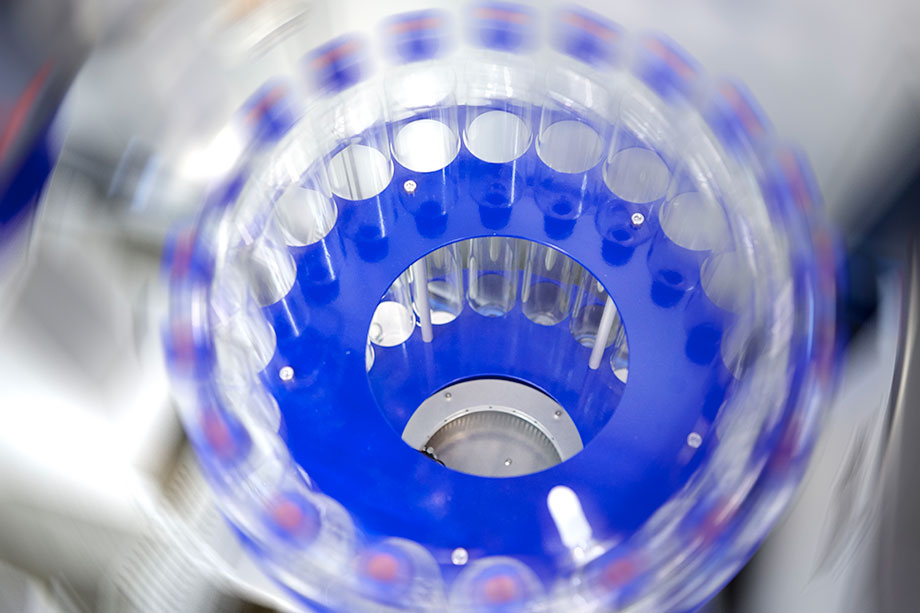

The system measures online the volume of each fraction before each cut is being discharged into an automatic fraction collector with 20 receivers. The fraction collector is equipped with an inbuilt electronic balance to measure the weight of each fraction. By replacing filled receivers the system can handle up to 80 cuts for the distillation of one sample. The receiver change is performed according to pre-selected cut temperatures or when a receiver is filled up to continue the cut sampling in the next receiver (to avoid overfillingof the receiver).

After the distillation the operator needs to weigh the gas trap as well as the flask residue by the external balance (part of delivery), the weights are automatically taken by the system and as a result the final data evaluation and TBP-curves in weight-% and volume-% are printed out and can be stored.

The system can optionally be equipped with an online density measurement system.

The system requires for operation water, nitrogen, compressed air and electricity to be supplied by lab infrastructure.

The following video shows the test procedure of the fire alarm system for PETRODIST 100 CC, manually activated.