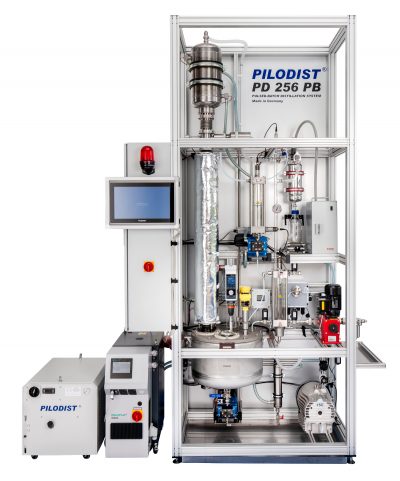

Highly versatile system for distillation of diverse mixtures of substances with a variable number of components in a broad range of quantities in one universal system

Developed for medium to large scale pilot distillation, the PD 256 offers a high degree of flexibility for processing different kinds of mixtures. Quantities as low as only a few liters up to large campaigns of 1000+ L can be processed with this single unit in automated and unattended 24/7 operation.

The system can separate different fractions (e.g., six fractions + residue) in an automated fraction distribution system with a separation efficiency up to 100 theoretical plates, depending on chosen column length and packing material.

The PD 256 is suitable for a variety of applications like:

- Pyrolysis oils and E-fuels

- Recycling of solvents

- Botanical extracts

- Food & Pharma

- Petroleum products

- R&D

Optimized software and automation features increase performance, ease of use and product quality. The system is modular and allows individual configurations. It can be configured with DN60 and DN100 diameter column segments, different column lengths and variable flask sizes.

Technical Data

| Material | borosilicate glass 3.3, SS316, PTFE, Kalrez | |

| Charge quantitiy | < 5 L to > 1000 L | |

| Operating temperature | up to 250°C | |

| Operating pressure | ATM … 1 Torr | |

| Column diameters | DN60, DN100 | |

| Column lenghts | One or more 1000 mm segments | |

| Throughput at 2:1 reflux ratio | Up to 30 L/h | |

| Dimensions (w x h x d) approx. | (w)2.40 x (h)2.90 – 4.50 x (d)1.5 m, depending on configuration |