Products

PD 250 GD continuous rectification system

Distillation system for continuous operation

The PD 250 GD is our most recent advancement in continuous distillation technology. Whenever it comes to lab- and pilot-scale simulation of large-scale thermal separation processes with a consistent feed composition, continuous distillation is the Read the rest

The PD 250 GD is our most recent advancement in continuous distillation technology. Whenever it comes to lab- and pilot-scale simulation of large-scale thermal separation processes with a consistent feed composition, continuous distillation is the Read the rest

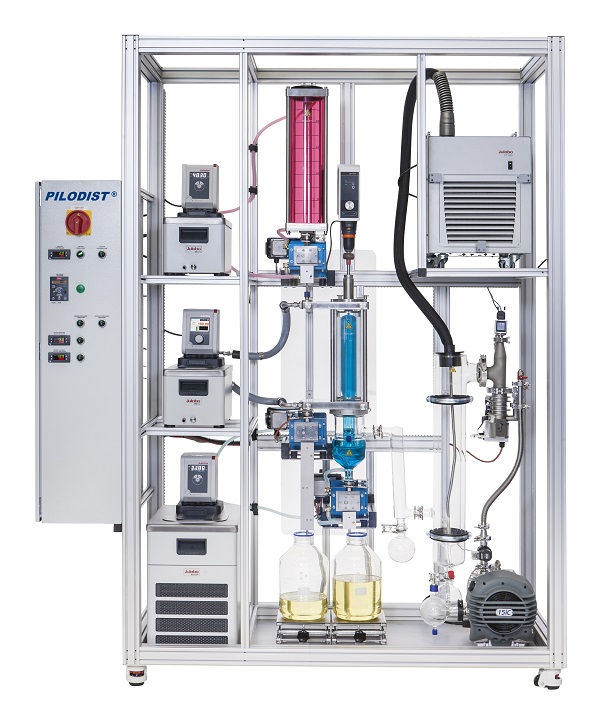

TF 1000 RC Wiped film distillation

Thin film rectification system for thermally sensitive materials

The heart of the TF 1000 RC is its double walled glass thin film evaporator, heated by thermal oil. Product is continuously fed in and distributed on the inner walls by PTFE Read the rest

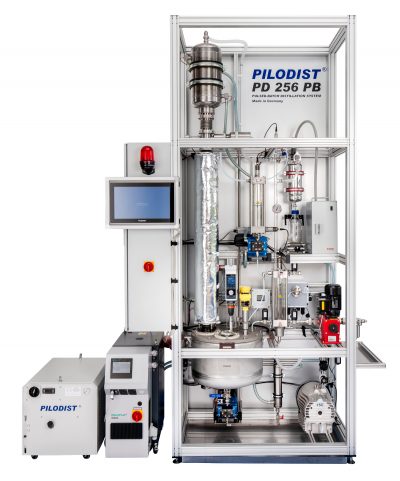

PULSEDIST 256 Distillation System

Highly versatile system for distillation of diverse mixtures of substances with a variable number of components in a broad range of quantities in one universal system

Developed for medium to large scale pilot distillation, the PD 256 offers a high Read the rest

PILODIST SP 1000 M

WIPED FILM MOLECULAR DISTILLATION SYSTEM

Wiped-film evaporator for short-path and molecular distillation

The short path distillation system is designed for the distillation of thermally sensitive products under vacuum. The system is used for organic products of high molecular weight and Read the rest

PILODIST TF 100 Thin-Film Distillation System

Thin film distillation system for laboratory use.

The distillation system has a liquid-tempered evaporator made of borosilicate glass with an integrated condenser and temperature-controlled inlet and outlet.

The system includes all peripheral parts necessary for operation, such as the Read the rest

ASTM D4929

PILODIST PD 4929 S

The new PILODIST PD4929S is an automatic distillation apparatus for the sample preparation according to ASTM D4929.

This standard test method for the Determination of Organic Chloride Content in Crude Oil requires a crude oil distillation Read the rest

PILODIST 104 BD – 10L

The PD104BD is designed for critical and sensitive products and does not contain any metal parts in direct contact with the sample. The system consists of a double jacketed 10L glass vessel with mechanical stirrer drive, precise oil tempered Read the rest

PILODIST 104 HT

Customized distillation system for fractional distillation of samples with high melting point. The system is designed for collection of product in single receivers. The system is supplied with 2 x interchangeable columns (concentric tube column, DN25 packed column).

Operation range Read the rest

PILODIST 104 HC – 200 L

New high capacity version of our most popular PILODIST 104 HC fractional distillation system series.

New high capacity version of our most popular PILODIST 104 HC fractional distillation system series.

The setup includes a 200 L stainless steel flask with a powerful 12kVA electrical flask heater as well as a stirring gear to Read the rest

PETRODIST 400 CC-A

New combined distillation system PETRODIST 400 CC-A

PILODIST is proud to introduce a new distillation system to combine 2 different distillation procedures according to ASTM D2892 (TBP) and D5236 (POTSTILL) by sharing some essential components. Each of the 2 distillation Read the rest

PILODIST SP 1000 CC

Wiped-film evaporator for short-path and molecular distillation

This is our new flagship for short path and molecular distillation. The SP 1000 CC is a turnkey ready system for laboratory use and small scale production and is optimized to cover nearly Read the rest